ARTICLE SUMMARY

Procurement is a business process in the fullest sense of the term. It plays a key role in business strategy, involves a number of workflows, and requires input or action from multiple departments.

Key takeaways

- Procurement is a complex process that consists of several workflows or integrated subprocesses, like the purchase process and the accounts payable process.

- 61% of CPOs agree that procurement-related risks have been on the rise, many of which have to do with the economic downturn, internal complexity (at product and organization levels), supply chain disruptions, and managing risk with suppliers.

- As business needs change, optimizing the procurement process with a low-code automation solution is essential for keeping up with competitor activity and process complexity, reducing process friction, minimizing errors, and improving business agility and savings.

Unlock higher procurement efficiency with the Definitive Guide to P2P Optimization

What is the procurement process?

Procurement is the end-to-end process of sourcing and obtaining goods and services from external suppliers in order for companies to achieve their strategic objectives.

Procurement process diagram and related workflows

Procurement is a complex process that consists of several workflows or subprocesses including approving vendors, issuing purchase orders, receiving goods, and paying invoices. Depending on the organization, other workflows may also take place within the procurement process.

Below are visual examples of the various workflows that make up the procurement process:

Why is the procurement process important?

According to a recent Deloitte survey, 61% of chief procurement officers (CPOs) agree that procurement-related risks have been on the rise over the past year. Some of the top risks highlighted in the report include economic downturn, internal complexity (at product and organization levels), and managing risk with suppliers. Additionally, there is a chance of potential supply chain disruption.

To minimize these risks, organizations need a procurement process that functions effectively even in difficult scenarios to help them keep their supply chain flowing and ensure that sourcing efforts are not disrupted. Learn more about sourcing vs. procurement.

What is modern procurement?

A modern procurement process uses technology or procurement solutions, like low-code automation or business process management software, to solve common procurement challenges.

Modern procurement prioritizes continuous process improvement and leverages technology to orchestrate processes, increase savings, and create a seamless, reliable, and streamlined process experience.

In a sense, modern procurement is both an immediate action and a long-term practice; the action of leveraging technology to improve procurement functions and efficiency, and the practice of continuously seeking ways to modernize the process and remain competitive.

Elements of a procurement process

Procurement, like any other process, is made up of a set of basic components and workflows. These components include the people, information, and work required to meet the process goal, as well as some specific workflows that help organize the steps in the procurement process.

Basic components

Every workflow consists of a set of basic workflow components. Sometimes these are referred to as “people, processes, and paper,” but it might be clearer to name them for what they are: actors, information, and work.

Standardize and automate your business processes to gain full control and visibility of your procurement operations

4 types of procurement

There are two main procurement types that businesses leverage for long-term success: direct and indirect. A third type of procurement focuses on short-term needs: services procurement, and a fourth type targets inventory stock and supply needs: goods procurement. Below is a brief recap of all four types:

1. Direct procurement

Direct procurement is a core business process that handles the purchasing of products or services that are required to produce value for customers. As the name implies, direct procurement has a direct impact on a company’s bottom line.

Key qualities:

- Directly impact revenue and customers

- Prioritizes building stable and reliable relationships with suppliers

2. Indirect procurement

Indirect procurement is a support process used to purchase services or products essential for day-to-day business operations but doesn’t necessarily provide direct value to customers or generate revenue.

Key qualities:

- Indirectly impacts the business and supports day-to-day business operations

- Prioritizes reducing procurement costs

3. Services procurement

Services procurement is for obtaining services either provided by a person or people for a specific purpose, like a speaker or serving staff for an event. It also includes services with a determined scope or deliverables.

Key qualities:

- Used to meet or fill short-term needs or for a specific purpose

- Typically deals with people-based services, but can include services like business software or platforms

4. Goods procurement

Goods procurement is the procurement of physical items, like raw materials, supplies, equipment, or wholesale items. Goods may be obtained by direct or indirect procurement methods.

Key qualities:

- Often kept as inventory for resale

- Subject to return if permitted by the supplier

- Careful inspection of goods upon receipt is imperative

The 5 Rs of procurement

Procurement has a few core tenets, the five Rs, or the five “rights.” They distill the purpose and goals of the procurement process into a few simple concepts.

Right quality

Finding and obtaining high-quality goods and services is a procurement priority. They must fit the needs of the buyer and supplier, and meet all specification requirements, as well. Quality, especially that of physical goods, may derive from the choice of the supplier but must be maintained by rigorous quality assurance programs on the part of all stakeholders.

Right quantity

Scenario: you receive an order, and check that there are enough materials on hand to satisfy it. Your stock is short a few pieces, so you order through your long-trusted supplier. Sounds simple. In the aftermath of the pandemic, however, that supplier now only ships in large increments, which, in turn, exceeds your inventory limits, budget, and lead time.

Quantity management is part of a bigger process known as strategic sourcing, a seldom-discussed but crucial aspect of procurement. It requires a detailed, fully transparent view of your stock and supply chain, as well as a trusted source of past data on which to make predictions for future orders.

Right price

No one wants to overpay, nor do they want to secure a seemingly sweet deal only to receive items of inferior quality. Price analyses for new suppliers (evaluating past sales for quality and reliability) are a good way to ensure the best price possible from the first interaction. Negotiations, the final step of pricing (for both new and existing suppliers), ensure that everyone wins; they keep costs at a minimum for buyers and suppliers alike.

Right time and place

“The right time and place” refers to on-time, accurate delivery. The procurement process can run smoothly and efficiently at every stage, but if the delivery date is missed, or if items are shipped to the wrong location, none of that matters. All the customer sees is a late delivery and the possible inconveniences they bring (bottlenecks, work stoppages, etc.).

On-time, accurate deliveries depend on several factors, the most important of which are packaging, transport planning, and demand management. Large entities like military sites may have several different shipping points on the same campus. Within the procurement process as a whole, few pieces of data are more essential, and more worthy of confirmation, than a customer’s need date, preferred carrier, and shipping address for each specific item.

Right source

Finding the right vendors is an essential part of procurement. You are choosing companies with whom you may eventually conduct long-standing business, so a rigorous vetting process should already be in place when a new vendor or supplier is considered. Criteria for evaluation include the company’s record of regulatory compliance, its history of quality and on-time delivery, and its industry reputation.

Procurement vs. purchasing vs. supply chain

Although the terms procurement and purchasing are often used interchangeably, they are not the same. Purchasing is the act of buying goods and services from a vendor or supplier. In this sense, it is purely transactional and deals with only the closing costs and actions. Procurement is a broader, more strategic process that is required to sustain the business.

Another topic that comes up with discussing procurement and purchase processes is the supply chain. A supply chain is a network between a company and the individuals (like suppliers and vendors), resources (like delivery and distribution), and technology (like finance or process management software) required to create and deliver a final product to customers.

All three of these live as complementary elements within the procurement process.

| Procurement | Supply Chain | Purchasing |

|---|---|---|

| The process of sourcing and obtaining products or goods necessary for business operations. | The network of individuals, resources, and technology required to create a deliver a final product. | The purely transactional part of the procurement process. |

Common procurement challenges

No process is perfect, and in today’s digital era, continuous improvement and digital solutions are a must-have. With the right tools, teams can easily solve common procurement challenges like:

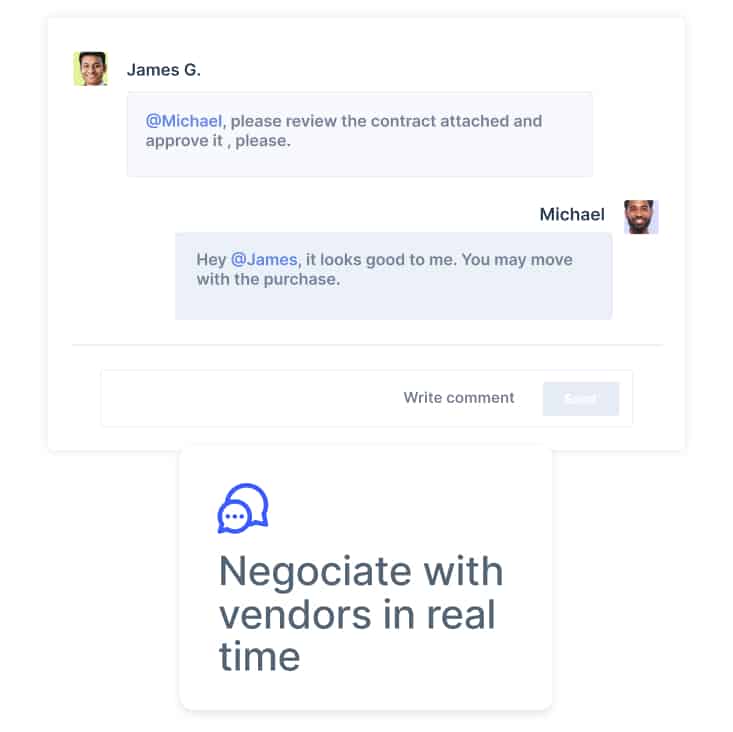

- Communication and collaboration

- Risk mitigation

- Process transparency

- Inaccurate or disorganized data

- Process analysis and forecasting

- Supplier management

- Contract management

- Information flow

4 procurement process workflows (and how to modernize them)

Business processes can usually be broken down into a series of workflows. Procurement is no exception. Although every business and organization will have a unique procurement process that’s built on specific needs and experience, we can imagine some of the most common workflows that occur in a typical procurement process.

1. Approving vendors

Identifying and vetting vendors is an important part of procurement. By establishing relationships with multiple vendors, a business can avoid supply chain disruptions and create incentives for better prices from the vendors.

Approving vendors may require input from a purchasing manager or the finance team. Information required may include logistics or tax information. With a low-code automation platform, teams are automatically notified when they’re assigned for review or when a deadline is approaching.

See an example of a vendor approval workflow.

2. Creating purchase orders

One of the most well-known workflows in procurement is the purchase order process. These usually originate with a request from an employee, but may also be automatically triggered by software that detects a change in inventory.

Copies of PO will likely be shared with a purchasing manager, warehouse, and finance teams. A low-code automation platform that can be integrated with existing software or databases that is responsive to real-time updates means fewer errors and better visibility. Plus, with audit trails and document centralization means you run can various approvals from a single platform.

See an example of a purchase order workflow.

3. Receiving goods or services

Once a need has been identified, and goods or services ordered, there will be a workflow for confirming and documenting receipt of those goods or services. Often this will include a three-way matching process.

See an example of a goods received workflow.

4. Paying invoices

A typical procurement process will also include paying for the goods or services that have been received. A reconciliation process between the invoice, PO, and goods received note (GRN) may be required. Do this all from a single platform, and implement automation and conditionals to ensure that all invoice payment tasks are assigned and approved in a timely manner.

See an example of a pay invoices workflow.

Find the right automation tool for your business with the Buyer’s Guide to Automation Platforms

10 procurement process steps

Step 1: Identify company needs

The procurement needs of each organization are unique. They will vary based on size, industry, products, customer sensibilities, risks, digital presence, priorities, etc. Some organizations may even choose to use different processes for specific products or customers.

But there is a basic blueprint for the procurement process that can be adapted to your particular circumstances and needs.

At a fundamental level, before researching and engaging in talks with vendors, a company needs to identify requirements and evaluate their validity. Asking questions such as — is this a genuine need? By when does the product/service need to be sourced? What criteria should it meet or what kind of features does it need to have? — helps the company gain clarity and prevent possible roadblocks at a later stage.

Step 2: Review and authorize purchase requisition

After the strategic analysis of the need for the procurement service, the next step is to kick off the operational aspect. The requesting team within a company sends its requirements to the procurement team, which then does a thorough review of the request. Approved requests are signed off and pushed down the workflow.

Step 3: Approve budget

Approved purchase requisitions are forwarded to the accounting team for vetting against the budget. Based on past engagements with vendors, industry data, etc. a certain cost estimate is generated and that budget is approved and allocated for this specific purchase.

By this stage, the company has confirmed the need for the product as well as earmarked a certain amount to procure it. You’ll like to work closely with your finance team during this step. Keep in mind that sometimes the best price isn’t the lowest price, but the best combination of what you pay and what you’ll receive.

Step 4: Review vendors

Most companies have an approved list of vendors with whom they have prior relationships. Procurement systems carry this data making it easier to select a vendor for this transaction. However, in the event of ambiguity with the vendor list (for example, this particular product has never been sourced before or past engagements have not been too successful to continue), exhaustive research is required to identify choices.

Step 5: Select the vendor

Usually, companies shortlist two or three vendors before selecting one. They then reach out to each of them to express their interest and also ask for quotes and other details such as the warranty expiration period and the level of support provided in the event of issues. These details help the company finalize a vendor to proceed with.

Step 6: Negotiate with the vendor

By now, the company is clear about its vendor of choice. This could be because they are happy with the pricing point, service levels are good, or they have a depth of experience. The company then begins to negotiate the actual price and terms of the contract with the vendor.

After a few back-and-forth discussions, the terms are agreed upon and both parties sign the contract and purchase order (PO) is raised. For pre-approved vendors, this may be a straightforward process where a price has already been agreed upon and hence, it’s only a matter of rolling out a contract and initiating a PO. By practicing good contract management it can make future engagements with vendors more streamlined.

Step 7: Receive goods or services

At this stage, the vendor dispatches the goods or provides the services they are hired for. On receipt of a shipment, the company ensures that the quality and quantity meet expectations and communicates in case of any concern.

In cases where a service is procured (for example, a food stall service in your company cafeteria), it’s likely to be an ongoing transaction and continuous assessment is done to ensure that the company’s needs are met.

Step 8: Three-way matching

Three-way matching is a match between the purchase order, vendor invoice, and the product delivery confirmation report (also referred to as packing slip or receiving document). This is an accounting process that is done totally by the products ordered, dispatched, and received. This helps to avoid errors such as early or late payments, unauthorized payments, and quantity mismatches.

Step 9: Approve supplier invoice payment

After a successful three-way match, it’s time to release the payment to the vendor. This is a straightforward step in which the accounting team approves the payment as per the conditions of the contract (for example, within 30 days of receipt of shipment).

Step 10: Update and maintain business records

Maintaining document repositories is an important step in procurement. Although we discuss this as a final step, it’s an ongoing part of the entire process where every financial and business transaction needs to be traceable. This is not only essential from an audit perspective but also useful to conduct postmortems that help understand the efficacy of the procurement process or decide whether to continue engagement with a vendor or not.

6 essential procurement methods

1. Open tendering

Open tendering, also known as competitive bidding, is a procurement strategy used primarily to obtain goods. An invitation to tender is released publicly or industry-wide to which vendors and contractors respond with bids; the lowest-price bid wins. Frequently used in government and public sectors, open tendering ensures fairness in vendor selection and healthy competition among vendors and contractors.

2. Restricted tendering

Restricted tendering occurs when a procurement team reaches out to a selected list of vendors and suppliers for project bids. Businesses use this strategy to obtain specific goods or services from suppliers they often already know. It saves time by a) limiting the number of bids to assess, and b) eliminating the vetting and approval phases of the procurement process altogether. Cost savings are built-in, as well. If the organization has previously used a supplier, the procurement team can easily find pricing from past sales.

3. Requests for proposals (RfPs)

An RfP is a documented announcement of an upcoming project, inviting candidates (vendors, suppliers, and contractors) to reply with a proposal outlining their services, methods, and pricing for that project. Candidates submit their proposals in two separate envelopes – one containing the technical proposal and the other containing the financial offer.

Phase II of the RfP process begins when the business receives the resulting proposals; they must carefully assess each one, issuing scores and comments. The team then narrows candidates down to a shortlist, selecting its winner from among the finalists. The technical offer is considered first and weighted, then the financial proposal is opened and scored. The winner is chosen based on the highest combined marks, not the lowest price.

4. Two-stage tendering

Two-stage tendering formally divides the RfP process into two separate stages. Stage 1 begins upon receipt of all proposal responses. The soliciting business evaluates the technical proposals only, scores and ranks them, and chooses a front-runner, who is then invited to engage in negotiations for an agreement.

In the second stage, contract negotiations are held. If an agreement is reached, the financial proposal is opened and If they break down or no joint decision is reached, the next vendor on the list is contacted, and negotiations begin again.

5. Requests for quotation (RfQs)

An RfQ is a document submitted to targeted suppliers to explore their products and solutions for a given project. This process is used primarily by businesses that need a constant stock of certain items. Responsive quotes received from suppliers are not formal bids or offers – they simply provide the inquiring business with pricing, terms & conditions, and a few other key pieces of data to help them choose a supplier. The inquiring business’s response to its chosen supplier most often appears in the form of a PO.

6. Single-source procurement

Single-source procurement is a rarely-used strategy within most industries because it does not encourage competition, fairness, or the best price or quality of goods or services requested. It is highly discouraged in industries like government and public works and used most frequently in emergency situations or in a continuation of previously unfinished work.

As the aforementioned industries may require multiple reasons to justify single-source procurement, any business using this strategy should include not only a checklist of those reasons on all POs and source documentation for the project but steps taken to find alternate vendors for the items, as well.

Optimizing your procurement process with low-code automation

In any business process, there are ways to reduce friction, minimize errors, and improve outcomes. Optimizing the procurement process becomes especially important as businesses scale and become more complex.

Build an efficient procurement process that scales

Business processes evolve over time, and the procurement process is no exception. What matters is how your team handles changes and adapts to real-time needs and competitors. Pipefy’s low-code automation software gives teams control of their procurement process. The platform’s visual interface makes implementation a snap, and a full toolbox of features and options gives you complete visibility and control.