ARTICLE SUMMARY

Attaining process efficiency doesn't have to be mysterious, complicated, or baffling. This quick guide provides a framework for making any process more efficient.

Process efficiency is one of the holy grails of business process management.

A great deal of time, energy, and other resources are devoted to increasing the efficiency of just about any process you can imagine. Unfortunately, most of us know from experience that the results of these efforts can be a very mixed bag.

This short article aims to tip the balance in your favor. Below, we quickly recap the basics of process efficiency and process improvement, consider some best practices (as well as mistakes to avoid), and provide a six-point framework to help you feel more confident in your ability to assess and improve the efficiency of any process you encounter.

What is process efficiency?

“Efficiency” refers to the ability to minimize the resources needed to produce a product or outcome. As process efficiency increases, the amount of time, money, and/or energy required to complete the process decreases. Efficiency tells us how successful we are at getting more out of our processes, while putting less into them.

Another way of thinking about efficiency is in terms of waste. The more efficient a process is, the less waste it produces. This waste may be a material resource or it could be defined as time or energy. Efficient processes minimize waste.

Discover a new way to manage and optimize your business processes

What is the impact of process efficiency?

We’ve established that efficiency reduces waste by producing more with less, but there’s more to it than that. When the efficiency of a business process increases, resources that were once tied up in activities that didn’t add value are now unlocked and available to be used elsewhere. Some of the ways efficiency translates into value include:

- Granting access to capital. Inefficiency freezes capital into activities that aren’t adding value to the business, creating undesirable opportunity costs. Efficiency makes those funds available for use in value-creating activities.

- Expanding time available. An efficiency process requires less time, which

- Increases customer value. Efficient processes can result in a better product, service, or experience for the customer.

- Improving process accuracy. Efficient processes may present fewer opportunities for errors or mistakes.

- Creating a better employee experience. Process efficiency can minimize or eliminate repetitive tasks, which means employees are free to focus on more meaningful work, build relationships, and solve problems.

In short, efficiency creates processes that minimize and conserve a range of resources, enabling organizations to achieve operational excellence and drive value-creating activities.

“Properly managed, the push for efficiency can free up capital and direct it to where it will create revenue, generate strategic growth options, and increase enterprise value.”

— Nick Araco Jr. & Steven Higgins, How Midsize Companies Can Maximize Growth and Efficiency

Productivity vs. efficiency

These two terms are often used interchangeably, although there is a subtle difference. Before we move along we should briefly address it.

According to the US Bureau of Labor Statistics, “productivity” refers to the “measure of economic performance that compares the amount of goods and services produced (output) with the amount of inputs used to produce those goods and services.” In other words, productivity measures how much work can be done with a given amount of resources.

“Efficiency,” on the other hand, refers to “the degree to which an organization minimizes the resources used to achieve an objective” (Management Accounting, 310).

Verdict: While productivity measures the ratio of resources (input) to work (output), efficiency tells us how well we are tilting that ratio in our favor, how good we are at doing less with more.

How do you determine process efficiency?

We’ve established that an efficient process is a process that reduces or eliminates waste – waste of time, waste of material, waste of resources. To track whether a process is doing this, companies track total process efficiency (TPE), or how well a process delivers products or services without generating waste.

That’s done by measuring criteria like:

- Total processing time, or how long it takes to produce a product from request/order to delivery.

- Resource utilization per unit of output, or how much time or effort spent per item produced.

- Non-value added cost, or added production costs that do not directly impact customers.

- Non-value added time, or time spent that does that directly impact production.

- Cost of quality, or total resources/tasks needed to prevent poor quality.

An efficient process improves production and keeps cost and time of production down – all without negatively affecting employee experience or quality of work, service, or product.

Common causes of inefficient processes

| Delays | Where and why is the work held up? If the delay is due to human capacity, consider automating some business steps in the process. |

| Redundancies | Are steps repeated unnecessarily? Does a step require multiple inputs where it could require only one? |

| Blind spots | If gatekeepers in the process lack visibility, they may be creating delays. Are approval managers aware of items that need their attention? If not, a reporting feature may solve the problem. |

| Fragmented data or flows | When processes fuse data or inputs from multiple platforms or tools, integration features can unify sources for a seamless experience. |

| Communication problems | Does everyone use the same terminology consistently? If not, this might be creating delays due to miscommunication. |

| Missing data | Are steps delayed because data is missing? Automation and forms features can ensure that work does not proceed without all the necessary information. |

| Unnecessary approvals | Approvals can hold up work in the flow. Are all approvals necessary? Can some steps in the approval flow be consolidated? |

| Bottlenecks | Not all bottlenecks are bad. In some cases, bottlenecks can prevent issues with quality. A workflow management reporting feature can help identify bottlenecks in business. |

Steps to improve business process efficiency

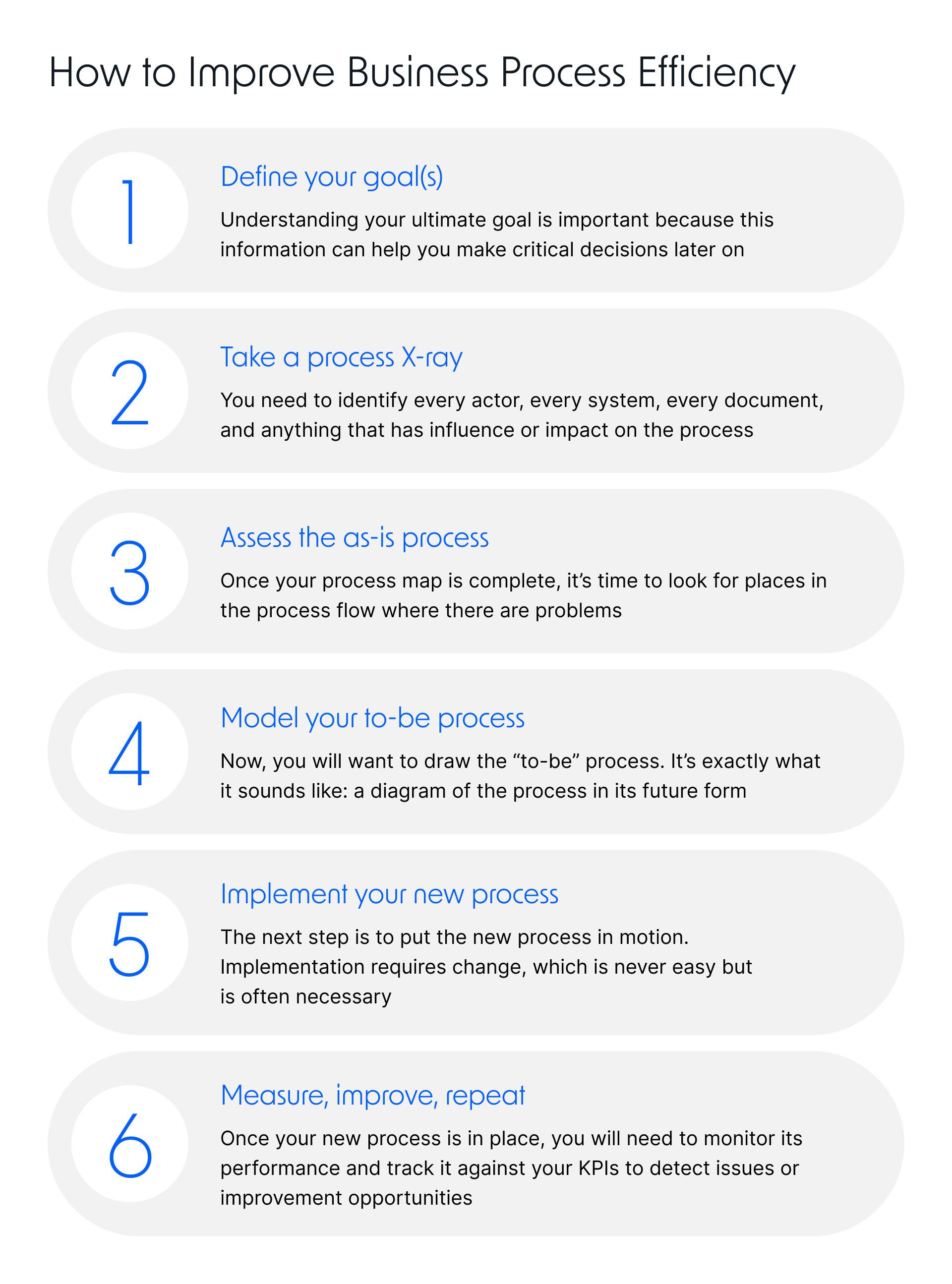

Step 1: Define your goal(s)

Even if your starting point is as straightforward as “make this process efficient,” it will be helpful to take that a step further. What do you want to achieve by increasing the efficiency of the process? What’s the driver behind the work you’re putting into this?

Understanding your ultimate goal is important because this information can help you make critical decisions later on. For example, if you want to make a process more efficient in order to make work less repetitive for employees (and thereby reduce turnover), then it doesn’t make sense to rework the process in a way that’s even more frustrating, even if the new workflow you’ve designed is so efficient that it wins an award and lands you on the cover of Efficiency Genius™ magazine. It’s still going to cost you employees and your objective still hasn’t been met.

The point here is to be wary of chasing efficiency for the sake of efficiency. Sometimes the efficient choice isn’t the right choice, and sometimes efficiency isn’t the real objective. If efficiency sacrifices the quality of the product, harms the customer relationship or diminishes the employee experience, it might not be the best choice.

“By default, it is usually assumed that the goal is to make the process more efficient (faster and cheaper) but this is not always, or even usually, a good assumption. Every organization doesn’t choose to compete as the faster, cheaper provider, and every process customer doesn’t choose the faster, cheaper alternative.”

— Alec Sharp & Patrick McDermott, Workflow Modeling, 2nd Ed.

Step 2: Take a process X-ray

Next you’ll need an X-ray of the process in its current state. You need to identify every actor, every system, every document, and anything that has influence or impact on the process. You need to map out what’s called an “as-is” process. This is usually referred to as process mapping or process modeling.

Process mapping usually starts with some detective work and ends with a diagram or flowchart that illustrates the process in all its complexity. These illustrations are usually called process flowcharts or workflow diagrams.

Keep in mind that mapping your process is going to take time and likely will require input from other people, i.e. those who know the process best. No one person is likely to have all the information you need to complete an accurate process map, so you may need to plan on spending time gathering insights from people who have their hands on the process. Prepare to dig deep and ask difficult questions. Thoroughness is of the essence when it comes to process mapping.

Step 3: Assess the as-is process

Once your process map is complete, it’s time to evaluate the effectiveness of each component in the flow. What you’re looking for now are places in the flow where there are problems, as well as opportunities to make improvements.

Depending on the level of detail, process maps can become complex. One way to prioritize the assessment process is to start by determining which steps of the process adds value to the final product or result of the process. Some non-value adding steps may be necessary in your flow, but others may be modified or eliminated.

Another area to prioritize are handoffs, or places where the work changes hands. Handoffs are notorious for causing delays or communication breakdowns.

Step 4: Model your to-be process

After you’ve mapped your process in its current state and identified the changes you want to make to improve its efficiency, you will want to draw a workflow diagram or process map of what’s called the “to-be” process. It’s exactly what it sounds like: a version of the process in its future form. Feel free to use standardized flowchart symbols or keep it simple by just using activity boxes for each step in the process.

Keep in mind that there are a few different types of diagrams that you can use. Swimlane diagrams are the most popular, because they give visibility into which teams own each step of the process and clearly show handoffs. Process flowcharts are also useful, especially for more complex processes.

Step 5: Implement your new process

After evaluating your current process, assessing its efficiency, and modeling your new process, the next step is to put it in motion. Implementation requires change, which is never easy but is often necessary.

The single most important thing you can do at this point is to communicate with the people responsible for the process. Listen to their ideas, answer their questions, and make sure they have a channel to provide additional feedback if problems arise within the new process flow. This will help you avoid the emergence of shadow processes or unplanned workarounds that often occur when a step in a process becomes frustrating or ineffective.

| Using automation to manage inefficiencies |

|---|

| Many of the root causes of inefficiency can be resolved with automation. That includes tasks such as creating and sending emails, notifying people when work needs their attention, collecting and organizing data, or moving items along in the flow. In addition, a well-known study estimated that 30% of work activities for more than half of the jobs in the US could be automated. That translates to a day and a half of extra time each workweek for a lot of workers. That’s time these workers could be using to add value to the company and engage in more satisfying work. Learn how to automate any process with Pipefy. |

Step 6: Measure, improve, repeat

Once your new process is in place, you will need to monitor its performance and track it against your KPIs. If/when issues or problems are detected, you will want to revisit the process and make changes or improvements as needed to make sure the process isn’t causing unnecessary frustration among your team.

Make sure you continue to solicit feedback from the team members doing the work; they will be your first line of defense when it comes to identifying process problems. Continual, feedback-based improvement can help keep the process healthy and employees happy.