Production planning and control Free Template

The Production Planning and Control template enables you to manufacture quality products, standardize the production process, and verify the work in progress. Strategically manage your resources, and keep every customer satisfied with your product.

Standardized process, quality products and happy customers

The Production Planning and Control template covers your process from end-to-end, helping you ensure everything runs in a standardized, organized, and hassle-free manner.

You want to deliver a great product to your customers, as fast as possible, and help them if they have any issues. From receiving the orders to production, expediting, and order tracking, this template will help you streamline the process and manage your resources strategically to keep your customers happy.

Take advantage of this customizable template to automate repetitive work, such as email messages or notifications to your team and clients. Keep improving your production line and making it more efficient by leveraging the process data Pipefy provides.

Less work for your team, better service for your customers

Centralized and standardized orders

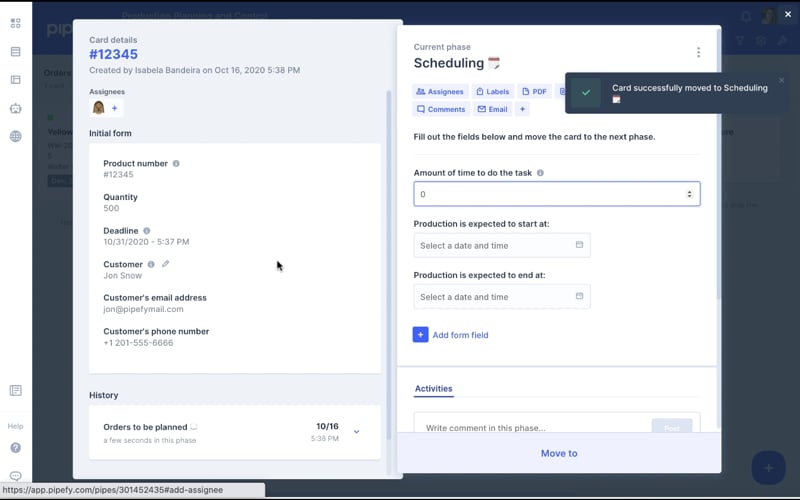

Easily collect all of your orders and visualize them in a single place. Create an online form to hold all the necessary information to get the production started.

High standards in the production line

Create checklists so your team won’t forget any steps. Standardization guarantees an error-proof process and high-quality delivery.

Data to make your process more efficient

Leverage dashboards and reports to quickly visualize your process data. Improve the production line, identify bottlenecks, and boost your team’s efficiency.

Easily receive and manage your orders

With the Production Planning and Control Template, you receive orders in a centralized, standardized and organized manner.

The Public Form allows your customers to make orders directly from an external link or via an embedded link on the company’s website, even for non-Pipefy users. The form is fully customizable and you can have more than one for different types of requests, grouping them in Portals.

Use our Request Tracker feature and allow customers to follow the progress of each order. And Email Templates enable you to automate common responses and notifications for rapid communication. Less work for your team, better service for your customers.

Raise the bar and deliver a great product

This template helps you determine the best and most cost-effective sequence of steps, and ensure that your team will follow them, without forgetting or skipping any important details. Arrange the different manufacturing operations in order of priority, and manage your resources strategically.

Centralize and organize all tasks for a more efficient process, and stop wasting time toggling between tools to monitor the manufacture of your product and your customer’s orders. Information you used to get in emails, spreadsheets, and forms will be in a single place.

Implement a standardized process by setting rules, creating checklists, and making sure every phase is followed. You can adapt our phase suggestions or customize the template for your own specific rules. This way, you ensure the quality of your products and deliver a high-level product, every time.

Save money leveraging data for a more efficient production line

With the Production Planning and Control Template, you can improve your production line efficiency by tracking goals and metrics.

Pipefy’s Dashboards allow you to visualize the data you want to follow closely. Extract metrics such as lead time, the number of orders received, how many were delivered on time, and your team’s productivity.

You can’t improve what you don’t measure but, with constant analysis, you can enhance your production line efficiency, identify bottlenecks, save time, money, and serve your customers faster.

Adapt this template for your needs and hit the ground running

Fast and simple to deploy

Get started with your process in minutes with this easy-to-use template.

No/low-code

Customize your unique needs without help from the IT department.

Wide app integrations

Connect your ERP, HRIS, CRM, and other existing tools with Pipefy to build a truly integrated operation.

Related templates

Simple To-do List

Manage your day-to-day activities in a more organized and productive way.

Collaborative Idea Management

Encourage an innovative and creative culture by enabling your team to share their ideas easily.