Last reviewed and updated by Team Pipefy in .

What are bottlenecks in business?

The term bottleneck refers to the way a bottle is shaped: wide body and a tapered neck. Because the neck tends to be the narrowest part of the bottle, it often restricts the movement of the bottle’s contents — like those glass ketchup bottles we’ve all struggled with at restaurants. Bottlenecks in business processes happen when work or request volume exceeds process capacity or bandwidth. In business, a bottleneck is a point (or points) in a process where the flow of work becomes delayed or breaks down completely.

Much like a production line, a bottleneck keeps a workflow from moving forward which leaves the workflow essentially useless and employees overloaded — especially if there are multiple bottlenecks affecting various processes at a single time.

While the visual of a bottleneck is more recognizable or obvious to spot in a production or assembly line, process bottlenecks can be just as clear once you understand how to spot what causes them.

Find the right tool to automate all your business processes with the Buyer’s Guide to Automation Platforms

Constraints vs. bottlenecks: What’s the difference?

A constraint is something that restricts the output of the entire process. It may be related to equipment, personnel, lack of information, or materials, or managerial, like policies or standard operating procedures.

A bottleneck is a constraint that impacts the output of a process and doesn’t allow it to achieve the determined goals.

A constraint can become a bottleneck if it begins to affect the overall output and productivity of a business process.

| Business process constraint | Business process bottleneck |

|---|---|

| Definition: Restricts output of an entire process, but doesn’t affect process goals Example: a shop’s internet is down, so transactions need to be processed manually Impact: A constraint may limit your production to “x” units a day; as long as the sales or production average is below “x,” then the constraint will not become a bottleneck. | Definition: Constraints that impact production or process goals Example: the only person with approval rights of certain expenses is on vacation Impact: If sales or production average is above “x,” then the constraint becomes a bottleneck. |

Common causes of process bottlenecks

There are many factors that can interrupt a process and cause a bottleneck, but the most common culprit is overload capacity.

Bottlenecks happen when a component or person in the process works beyond their capacity and can’t handle any additional demand. Bottlenecks happen when the incoming workload is arriving at a certain point more quickly than the point can handle, limiting the overall throughput of the whole process. This prevents business processes from running smoothly or efficiently. Common causes of bottlenecks can include:

Legacy software

Even with the most qualified and productive team, legacy software that is slow, glitchy, prone to crashing, or doesn’t play well with other software or tools will affect productivity and prevent an efficient process from working properly. To overcome this obstacle, teams will need to find a way to achieve stack extensibility.

Manual data processing

Manually collecting, entering, and updating data into systems and databases may actually be more harmful than it is helpful because it introduces issues like errors or duplicated data. This not only introduces mistakes but also creates potential risks like fraud, over or underpayments, and customer information errors.

Outdated workflows

If the workflows that make a business process are not working, then the business process as a whole is, by default, also not working. This can have a big impact on overall production, collaboration (both within and across teams), and efficiency.

Too much time spent on repetitive tasks

If someone spends five hours every week doing the same task, like drafting and sharing an email that can be standardized and automated, then that’s 20 hours spent every month doing the same thing over and over again.

Teams or individuals working beyond their capacity

When a business workflow includes approvals or a review from individuals that don’t have the bandwidth to do that, then the possibility of a bottleneck is high.

Types of business process bottlenecks

Bottlenecks occur in all types of business processes. They fall into one of two categories: short- and long-term. A short-term bottleneck is usually a temporary or circumstantial blocker and doesn’t grow into a more significant problem. Example: An employee goes on vacation or a computer is temporarily unavailable due to an update.

A long-term bottleneck is a systemic blocker that consistently occurs and significantly slows down the progression of workflows over time, leading to more significant issues. Example: Business software that keeps crashing and ends up generating a queue.

Within these two categories, there are three types of bottlenecks. Here’s a breakdown and examples of all three:

| Regulatory | Operational | Infrastructure |

| Bottlenecks created by incomplete or ineffective procedures or rules | Bottlenecks that result from people, systems, or tools that lack the capacity to match work volume | Bottlenecks caused by a lack of proper resources or process structure |

| Examples: A process that once worked no longer works following a large company shakeup; a process wasn’t mapped out before being built; too many rules slowing down a workflow. | Examples: An approval is required in order for a workflow to progress; a delay in an interconnected process negatively affects other processes and departments. | Examples: Critical actors or tasks were left out during process mapping which now creates delays; the wrong software was chosen to run a process, creating issues for productivity. |

Why bottlenecks are bad for business

In addition to stalling workflows, process bottlenecks can cause:

1. Higher resource costs and loss of profits

When resource costs go up, then the cost of production goes up. And if production output is low or below average, then profits will eventually be at a loss because the money that’s going in isn’t being made back.

2. Missed deadlines and lower productivity

A business process is made up of workflows that are owned and handled by various individuals. So if one person falls behind or is keeping a task from moving forward, then that can impact deadlines and tasks owned by others. And if deadlines are being missed, then the output of a process will also be affected.

In addition to stalling work, bottlenecks create opportunities for additional workflow breakdowns, especially within complex, interconnected business processes. Think finance, HR, IT, or customer success — all departments that require the many moving parts of interrelated processes to flow seamlessly.

3. Increase in employee burnout and turnover

Bottlenecks can indirectly impact a company’s key partner: its employees. By not investing time and resources into addressing and resolving bottlenecks — whether that means updating legacy software or hiring another team member to improve bandwidth — then employees may not feel valued and seek other opportunities.

4. Strained relationships with suppliers and/or customers

When a bottleneck affects a critical approval, like in the accounts payable process, that ultimately leads to missed or delayed payments to suppliers, which can affect the overall reliability of you as a customer. This can affect discounts, credits, or any other perks that may come from working with a supplier that deems you a stable account.

This can also affect your customers, especially if production is slow due to missing items, supplies, or delayed order processing or customer support.

Examples of business process bottlenecks

Below are some examples of bottlenecks in various types of processes:

Project management and service request processes

These bottlenecks are usually information, people, time, and communication. For example, if an approver is not reviewing assignments in a timely manner, requests can pile up and affect the overall output of a process.

Production and supply chain processes

While critical to production, factors such as sourcing machinery, raw materials, and suppliers can create bottlenecks if there are any delays or limitations.

How to find a bottleneck in your business process

A process is only as efficient as its most vulnerable point. The best way to resolve process bottlenecks is to learn how to spot them before workflows become congested.

Spotting a process bottleneck takes time and attention, but learning how to do so can keep small pains from growing into bigger problems. Here are two tips for spotting a bottleneck:

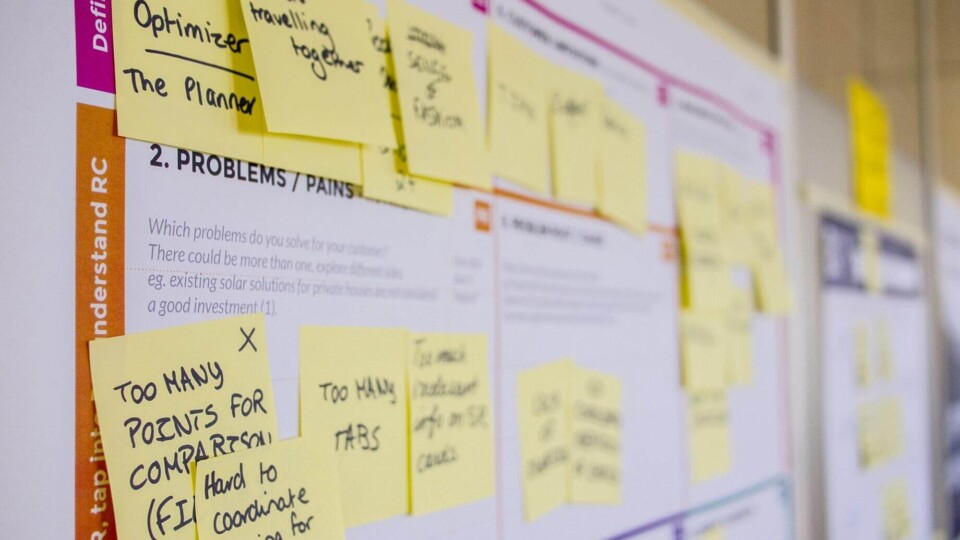

1. Map your processes

Mapping processes allows you to take a broader perspective when analyzing a process’s overall flow and performance. Observe each process step, its resources, interactions, workflow lead time, and task backlog. This way, you can identify what is restricting production capacity and performance which will reveal existing bottlenecks.

There are a few tools you can use to map your processes: a pen and paper, a flowchart using standard symbols, or a tool like business process management software. Thoroughly analyzing your processes may be just what you need to find those unforeseen improvement opportunities to clear out your bottlenecks.

2. Look at the data

The truth is always within the numbers. Start by looking at the data related to your process to assess what’s causing bottlenecks, and ask: Are tasks usually stalled at a certain point? Is there a trend related to delays that link back to a particular person or owner? Trends, themes, and patterns is what you should be looking for as you analyze your process data.

3. Go to the people involved

While data usually reveals process truths, it’s not the only truth that needs to be considered. Speaking with the people that are involved in a process provides an additional layer of insight that data may not offer, such as:

- Are people overwhelmed with the amount of work?

- Are there communication breakdowns?

- Are teams not adequately staffed?

4. Conduct a workflow analysis

Once you’ve gathered data and spoken to the actors involved in a process, it’s time to take a closer look at the details. A workflow analysis is the opportunity to review the order of tasks and activities that produce a specific workflow outcome. As you review, look for redundancies, existing bottlenecks, and other issues that may create future bottlenecks.

For more on how to identify bottlenecks, check out this post to learn how to master the task in just five steps and how to make it a part of your continuous process improvement plan.

How to implement business process bottleneck improvements

1. Search for creative solutions to the problems

When you single out your process bottlenecks, you can look at them objectively and start researching ways to solve these problems. This is another step where it’s great to bring in all involved team members. Working as a team with different views and ideas may be what you need to find creative and effective solutions.

Besides providing a wide range of ideas, stimulating interaction will also keep the team integrated and committed to the changes that may prove to be necessary.

2. Always have alternatives to solutions

Do not disregard any alternative presented while looking for solutions to your problems; consider all options. Keep your plans B, C, and D just in case plan A doesn’t perform as well as planned.

It is essential to monitor your processes regularly to keep them updated and effective. Even old and established processes may lose their effectiveness and need an update from time to time. You can’t set processes in stone; they must be flexible enough to adapt to internal and external changes.

3. Continuously search for and implement bottleneck improvements

The team must be in the loop of all steps of the process improvement implementation, from mapping the processes to identifying bottlenecks, searching for solutions to elaborating and implementing an action plan.

Keep the improvement process dynamic and continuously re-evaluate the results. Most likely, the first idea for a solution will not be the perfect answer to the problem. However, it is crucial to put your plan into practice to have real-world feedback and continue optimizing the workflow. Continuous improvement by planning, acting, checking, and evaluating will provide you with information and data to make any adjustments.

Solve process problems with low-code automation software

With a low-code business process automation platform, teams are able to manage and even eliminate bottlenecks from their business processes. Pipefy’s low-code automation helps you control your processes and reinforce the points that need it most.

Establish a streamlined, centralized, and error-proof workflow with customizable features like:

- Rules and conditionals: No more delays due to missing or incomplete information. With rules and conditionals, you can ensure that all relevant information is present before a task or request moves into the next phase.

- Automation: Tasks are automatically moved to the next phase of a process, and notifications instantly alert owners of progress or when their review is required.

- Dashboards: Make it easy to see the status of all tasks in a workflow, and gather important business intelligence related to processes like

- Integrations: No more hopping back and forth between platforms or multiple spreadsheets. By integrating your existing software with Pipefy, you can save time and prevent delays and errors due to manually entering data. Information is collected, organized, and added to a process in real time.

If Not Now, When?

No fluff here—that question’s for real. Why stick with outdated service management if there’s already a smarter, faster, more reliable way to get things done?

When speed and adaptability are non-negotiable, old-school workflows just can’t keep up. Embracing automation, AI, and modern process management isn’t optional anymore—it’s essential.

If you’re ready to scale without burning out, it’s time to lean into the shift. The future of service management isn’t coming—it’s already here. And Pipefy’s ready to help you get there with AI-powered workflows that work with you, not around you.

Want to see it in action? Let’s get that demo on the calendar.